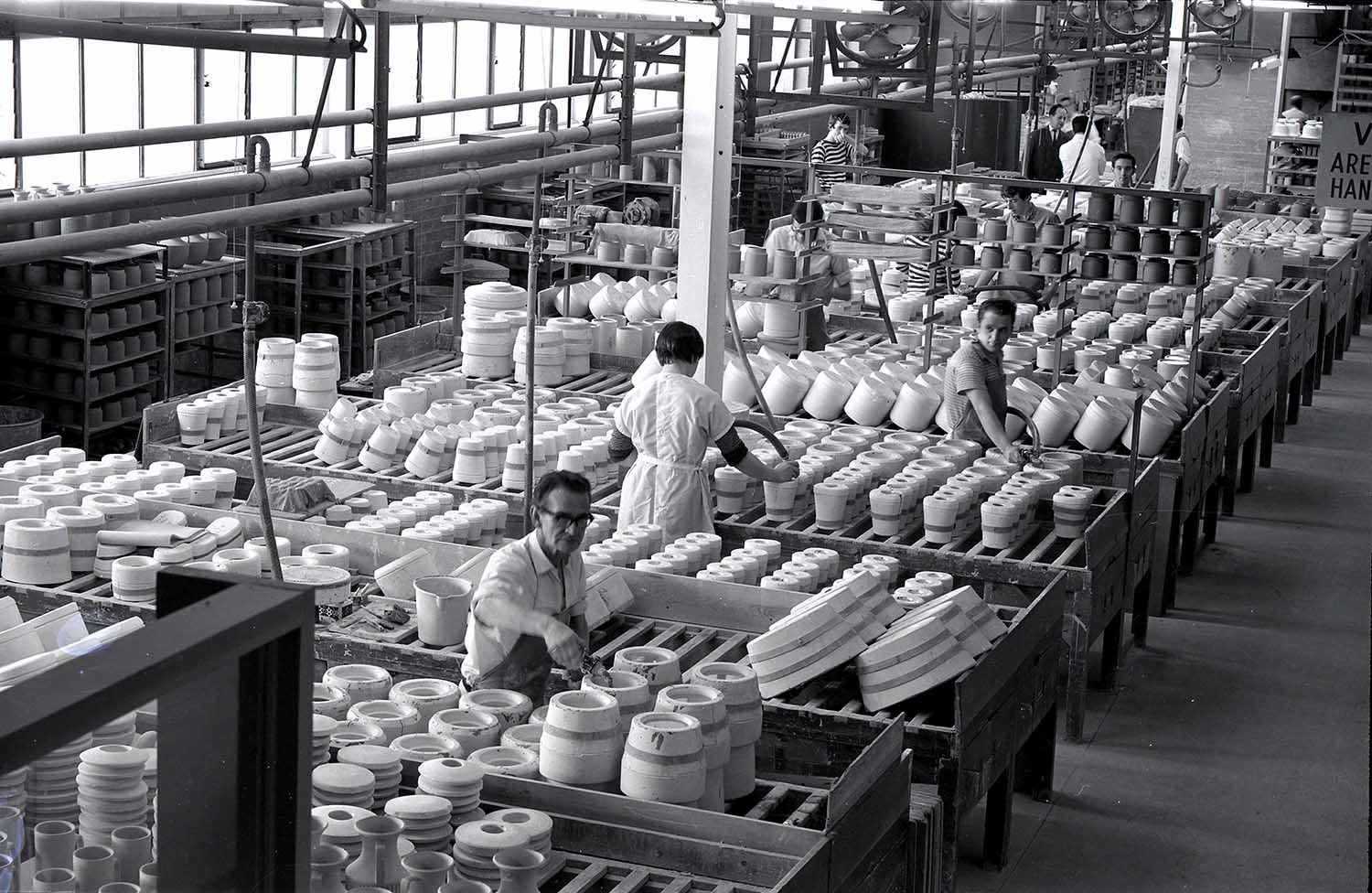

Manufacturing piping solutions are the unsung heroes of numerous industries, providing the crucial infrastructure that enables the transport of liquids, gases, and granular materials within factories and facilities. These systems are significantly transforming in today’s fast-paced and dynamic manufacturing world. Innovative technologies and materials reshape how piping solutions are designed, fabricated, and installed, resulting in more efficient, cost-effective, and sustainable processes.

The Role of Piping Solutions in Manufacturing

Piping solutions play a fundamental role in manufacturing operations, ensuring the safe and efficient transfer of materials essential for production. Whether carrying raw materials to machines, transporting finished products, or managing waste and by-products, piping systems are indispensable components in the industrial landscape. Their significance can be categorized into the following key areas:

- Material Transport: Piping systems are the backbone of material transport within manufacturing facilities, efficiently conveying liquids, gases, and solids. For example, in the food and beverage industry, stainless steel piping ensures products’ safe and hygienic transfer.

- Process Efficiency: Well-designed piping solutions streamline production processes, reducing downtime and improving operational efficiency. They enable precise control of material flow and distribution.

- Safety and Environmental Compliance: Properly engineered piping systems ensure the safe handling of hazardous materials, protecting workers and the environment. Compliance with regulations and standards is a top priority.

- Sustainability: Modern manufacturing is increasingly focused on sustainability. Innovative piping solutions contribute to reducing energy consumption, emissions, and material wastage. This, in turn, positively impacts a company’s environmental footprint.

Designing Piping Solutions for Manufacturing

In manufacturing, piping solutions are highly specialized, each designed to meet the unique requirements of the industry and application they serve. To maximize their effectiveness, these solutions are tailored to the specific needs of the manufacturing process. The following factors play a vital role in their design:

- Material Selection: Choosing the right material for a piping system is critical. Common materials include stainless steel, carbon steel, plastic, and various alloys. The choice is influenced by factors such as material compatibility, temperature, pressure, and the nature of the materials being transported.

- Routing and Layout: The piping network’s design must consider the manufacturing facility’s layout, ensuring an efficient and logical path for material flow. Minimizing bends, turns, and elevation changes helps reduce energy consumption and maintenance costs.

- Size and Capacity: Piping must be sized appropriately to handle the required flow rates. The pipe diameter, thickness, and type must be selected to accommodate the intended load, which often involves complex engineering calculations.

- Pressure and Temperature Control: Some manufacturing processes involve extreme pressure and temperature conditions. Piping solutions must be designed to withstand and regulate these conditions, ensuring safe and efficient operation.

- Modularity and Scalability: Expanding or modifying piping systems easily is crucial for adapting to changing manufacturing needs. Modular designs make it possible to add or remove sections of piping without extensive disruption.

Innovative Materials and Technologies

In recent years, manufacturing piping solutions have benefited from groundbreaking materials and technologies, contributing to more efficient and sustainable operations. Some notable innovations include:

- Composite Materials: Fiberglass-reinforced plastic (FRP) piping is gaining popularity due to its resistance to corrosion, lightweight nature, and durability. FRP piping is becoming a go-to choice in industries like chemicals and water treatment.

- 3D Printing: Additive manufacturing, commonly known as 3D printing, is revolutionizing the fabrication of specialized piping components. It offers flexibility in design and reduces lead times for custom parts.

- Smart Piping Systems: Integrating sensors, actuators, and control systems into piping solutions allows real-time monitoring and adjustments. This “smart” technology enhances process control and predictive maintenance, reducing downtime and improving efficiency.

- Advanced Insulation: Improved insulation materials and techniques reduce heat loss in steam and hot water systems. This results in energy savings and lower operational costs.

- Corrosion-Resistant Coatings: Coatings and linings have improved, providing longer service life and enhanced corrosion resistance for piping systems exposed to aggressive environments.

Maintaining Piping Systems

Preventing pressure drop is a paramount concern in maintaining efficient piping systems. Pressure drop can occur due to pipe blockages, corrosion, or improper sizing, decreasing flow rates and reducing system performance. Regular maintenance, proper material selection, and technology like flow sensors can be crucial in mitigating and preventing pressure drop issues, ensuring that piping systems function optimally across different industrial applications.

Manufacturing piping solutions are the silent heroes of the manufacturing world, ensuring the smooth flow of materials and processes in various industries. The design, materials, and innovations in this field are continuously evolving to meet the specific needs of each sector while also addressing the growing concerns of sustainability and efficiency. As we look to the future, we can expect even more remarkable advancements that will further enhance the role of piping solutions in manufacturing, promoting safety, efficiency, and environmental responsibility.