Project: Chop Stick

Designed by Visiondivision

Location: Indianapolis, Indiana, USA

Project Team: Anders Berensson & Ulf Mejergren (Architects) Donna Sink (Local Architect) Dave Steiner (Engineer) Lisa Freiman & Sarah Green (Curators)

Client: Indianapolis Museum of Art

Project Year: 2011-2012

Photographs: Donna Sink

Images: Visiondivision

Website: www.visiondivision.com

Talented Visiondivision architects share with us their engaging new project created for a park in Indiana, to fully understand the project read their description and view the images after the jump:

From the Architects:

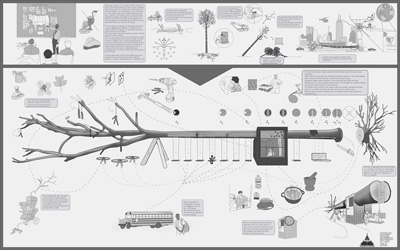

The design is based on the universal notion that you need to sacrifice something in order to make something new. Every product is a compound of different pieces of nature, whether it is a cell phone, a car, a stone floor or a wood board; they have all been harvested in one way or another. Our project is about trying to harvest something as gently as possible so that the source of what we harvest is displayed in a pure, pedagogic and respectful way—respectful to both the source itself and to everyone visiting the building.

The raw material we selected is a 100-foot yellow poplar tree, the state tree of Indiana, known for its beauty, respectable size, and good properties as hardwood. We found a great specimen standing in a patch of forest outside of Anderson, Indiana. Our goal is to make the best out of this specific poplar tree, from taking it down and through the whole process of transforming it into a useful building that will be part of one of the finest art parks in the United States. As the project proceeds, we continue to be surprised by all of the magical features that are revealed in refining a tree into a building; both in the level of craftsmanship and knowledge of woodworkers and arborists, and also of the tree itself.

The first step is to cut down the tree, which is done when the ground is dry enough to manage a crane on the site, with special mats placed on the ground to secure the crane’s operation. A cushion of small, already chopped-down trees is created to reduce the impact of the tree’s fall and to keep the majority of its limbs intact.

The tree is then transported to the park site, where it becomes the suspended horizontal beam of this new structure, which will be almost entirely made out of the tree itself. The tree’s bark is removed to prevent it from falling on bystanders, a process that occurs naturally as the moisture content in the wood drops, causing the tree to shrink and the bark to lose its grip. Craftsmen loosen entire cylinders of bark from the trunk that are then flattened and cut into a standard shingle length. The shingles are carefully stacked and placed under pressure to avoid curling. The stacks are then kiln dried to the proper moisture content, sterilized, and kept in climate-controlled storage until they are ready for use. Bark shingles are very durable, long lasting (up to 80 years), and maintenance free.

After debarking, pieces of wood are extracted from the suspended tree and used for each of the components of the concession stand; structural support of the entire construction, pillars and studs for the kiosk, swings under the tree for kids, benches and tables to be placed under the tree’s crown, from which special fixtures made out of branches will hang. Many school children visit 100 Acres, and we had those kids in mind when we decided to hang swings from the tree.

On a smaller scale, we are exploring ways to use other parts of the tree in the concession stand, including its root system, which is separated from the tree when cut down. The roots have many edible features, such as root bark used to make tea and tonics that could be sold in the kiosk, for example. Pressed leaves and flowers taken from the tree will be ornaments in the front glass of the kiosk. There is also the possibility of extracting honey from poplar tree flowers, which could be something for sale on site. The branches that are less than five inches in diameter are cut away to prevent eventual rotting, and those can be used for details such as legs for the chairs and tables, or grinded down into sawdust for use as insulation.

One Comment

One Ping

Pingback:Chop Stick by Visiondivision